|

While the application of plastic parts in various fields are constantly expanding, and the demand on sharp reduction in the cost of production as well as shortening of the cycle time of products entering the market, have drastically increased the pressure of the manufacturers. Proprietors' thirst for more understanding in the field of injection molding mold-flow analysis are becoming more and more urgent by days.

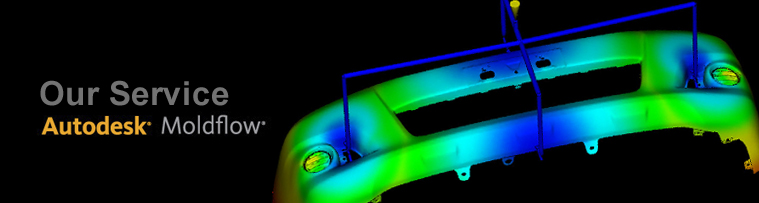

Moldflow can assist in optimizing the design of plastic parts & injection molds. It also looks into the flow process of injection molding. This overall reduces the high cost of production spent on creating prototypes, eliminating the flaws on manufacturing, and greatly helps in reducing the time spent on releasing new innovative products into the market. |